Product Description:

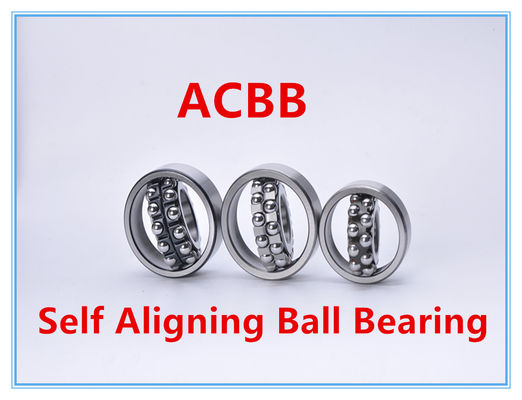

The Self-aligning Ball Bearing, model 22322, is a high-performance bearing designed to provide exceptional reliability and efficiency in various industrial applications. Known for its unique ability to compensate for shaft misalignment and shaft deflection, this bearing is an ideal choice for machinery that operates under heavy loads and challenging conditions. The self-aligning nature of this bearing makes it highly versatile, capable of maintaining optimal performance even when shaft alignment is not perfect, thereby reducing maintenance needs and extending equipment life.

This Self-aligning Ball Bearing belongs to the category of self-aligning spherical ball bearings, which are engineered to accommodate angular misalignment between the shaft and housing. This feature is critical in applications where shaft deflection or mounting errors can occur, as it prevents premature bearing failure and minimizes vibration and noise. The design of this self-adjusting ball bearing includes two rows of balls running on a common spherical raceway in the outer ring, allowing the bearing to self-align and adjust automatically to misalignment.

The bearing’s bore size ranges from 5 mm to 80 mm, offering a wide selection to suit different shaft diameters and application requirements. This range ensures that the bearing can be integrated into a diverse array of machinery, from small motors and pumps to larger industrial equipment. The internal diameter of the bearing is 75 mm, providing a robust inner dimension that supports the bearing’s load capacity and operational stability.

One of the key performance indicators of this Self-aligning Ball Bearing is its vibration ratings, which are categorized as Z1V1, Z2V2, and Z3V3. These vibration levels indicate the bearing’s capability to operate smoothly and quietly under varying conditions, with each rating representing different vibration intensity standards. Bearings with lower vibration ratings, such as Z1V1, are particularly suited for high-precision applications where minimal noise and vibration are critical. This feature makes the bearing suitable for use in sensitive equipment, including precision instruments and high-speed machinery.

The model 22322 is built with high-quality materials and advanced manufacturing techniques to ensure durability, corrosion resistance, and long service life. It is designed to withstand heavy radial and axial loads, making it suitable for applications in automotive, aerospace, industrial machinery, and agricultural equipment. The self-aligning capability of this roller bearing reduces the stresses caused by misalignment, which in turn decreases wear and tear on adjacent components, contributing to overall system reliability.

Packaging options for the Self-aligning Ball Bearing model 22322 are flexible and cater to different customer needs. It is available in industrial bulk packaging for large-scale applications, individual packaging for ease of handling and installation, and customized packaging tailored to specific requirements. This ensures that the bearing can be shipped and stored safely, maintaining its integrity until it is ready to be installed.

In summary, the Self-aligning Ball Bearing 22322 is a versatile and reliable component that excels in applications requiring self-alignment and vibration control. Its wide bore size range, robust internal diameter, and multiple vibration ratings make it adaptable for numerous industrial uses. Whether referred to as a Self-aligning Roller Bearing, Self-adjusting Ball Bearing, or Self-aligning Spherical Ball Bearing, this product stands out for its ability to enhance machinery performance, reduce maintenance costs, and extend operational life. With flexible packaging options, it is well-suited to meet the demands of various industries, making it a valuable addition to any mechanical system requiring dependable bearing solutions.

Features:

-

Product Name: Self-aligning Ball Bearing

-

Bore Size: 5 - 80mm

-

Cage Material: Pressed Steel / Brass / Polyamide

-

Misalignment Capability: Up to 3 Degrees

-

Thickness: 12mm

-

Type: Self-aligning Ball Bearing

-

Features Self-aligning Spherical Ball Bearing design for enhanced performance

-

Suitable for applications requiring Self-aligning Bearing Unit functionality

-

Durable and reliable Self-aligning Spherical Ball Bearing for various industrial uses

Technical Parameters:

|

Product Name

|

Self-aligning Ball Bearing

|

|

Model

|

22322

|

|

Internal Diameter

|

75 mm

|

|

Width

|

Varies (commonly 7mm To 40mm)

|

|

External Diameter

|

32 mm

|

|

Outside Diameter

|

19 - 170 mm

|

|

Holder

|

Steel Holder

|

|

Package

|

Industrial, Individual, Customized

|

|

Vibration

|

Z1V1 | Z2V2 | Z3V3

|

|

Misalignment Capability

|

Up To 3 Degrees

|

Applications:

The Self-aligning Ball Bearing is a versatile component widely used in various industrial applications due to its unique ability to accommodate misalignment between the shaft and housing. This self-adjusting ball bearing is designed with a steel holder that ensures durability and long service life, making it an ideal choice for demanding operational conditions. With an outside diameter ranging from 19mm to 170mm and widths commonly varying between 7mm to 40mm, these bearings can be tailored to fit a broad spectrum of machinery and equipment.

One of the primary application occasions for the Self-aligning Bearing Unit is in heavy machinery where shaft deflection or mounting errors are common. Industries such as manufacturing, mining, and construction often rely on these bearings to maintain smooth operations despite misalignments. Their self-aligning capability reduces maintenance needs and prevents premature bearing failure, thus enhancing equipment reliability and uptime.

In agricultural machinery, the self-aligning bearing unit plays a crucial role in supporting rotating shafts exposed to uneven loads and harsh environments. The steel holder construction protects the bearing components from contaminants and mechanical stresses, ensuring consistent performance during prolonged use. Additionally, the customizable packaging options—ranging from industrial bulk shipments to individually packaged units—allow for convenient integration into various assembly lines and maintenance schedules.

Another common scenario for deploying self-adjusting ball bearings is in conveyor systems and material handling equipment. These systems often experience shaft misalignment due to structural shifts or load variations. The self-aligning ball bearing’s ability to automatically adjust to angular misalignments ensures minimal friction and wear, which translates to smoother conveyor operation and extended service intervals.

Furthermore, the Self-aligning Bearing Unit is frequently utilized in electric motors and pumps, where precision and reliability are paramount. The bearing’s design accommodates shaft deflections and misalignments without compromising rotational accuracy, thereby supporting efficient power transmission and reducing energy losses. Customization options in the width and outside diameter allow engineers to select the perfect fit for their specific applications.

In summary, the Self-aligning Ball Bearing is an essential component for applications requiring tolerance to misalignment and robust performance. Its steel holder, variable widths from 7mm to 40mm, and outside diameters between 19mm and 170mm, combined with customizable packaging options, make it highly adaptable for industrial machinery, agricultural equipment, conveyor systems, and electric motors. The self-aligning bearing unit’s self-adjusting characteristics ensure enhanced durability, reduced maintenance, and reliable operation across a wide range of scenarios.

Customization:

Our Self-aligning Ball Bearing products offer extensive customization services to meet your specific application needs. With widths varying commonly from 7mm to 40mm, we ensure the perfect fit for your machinery requirements. The dynamic load capacity of 8710 guarantees reliable performance under demanding conditions.

Customers can choose from a range of cage materials, including pressed steel, brass, and polyamide, allowing for tailored solutions based on environmental and operational preferences. The outside diameter of our Self-adjusting Ball Bearings ranges from 19mm to 170mm, providing versatility across various equipment sizes.

Additionally, we offer options to accommodate different vibration levels with configurations such as Z1V1, Z2V2, and Z3V3, enhancing the operational stability of the Self-aligning Ball Bearing in diverse environments. Trust our customization services to deliver high-quality, precisely engineered Self-aligning Ball Bearings that optimize performance and longevity.

Support and Services:

Our Self-aligning Ball Bearings are designed to accommodate misalignment and provide smooth, reliable operation in various applications. For technical support, please ensure that the bearing is installed according to the specified alignment guidelines and operating conditions to maximize performance and service life.

If you encounter any issues or require assistance in selecting the correct bearing type or size, our technical support team is available to provide expert guidance and troubleshooting.

We also offer comprehensive services including bearing inspection, maintenance advice, and replacement recommendations to help maintain optimal machinery performance.

For detailed product specifications, installation instructions, and maintenance procedures, please refer to the product manual or visit our online resources.

Regular lubrication and proper handling are essential to prevent premature failure and ensure long service life of the Self-aligning Ball Bearings.

Packing and Shipping:

Each Self-aligning Ball Bearing is carefully packaged to ensure maximum protection during transit. The bearings are first wrapped in anti-corrosion paper and then placed in a sturdy plastic or metal container to prevent any damage from moisture or dust. The containers are then securely packed into durable cardboard boxes with appropriate cushioning materials such as foam or bubble wrap to absorb shocks and vibrations.

For bulk orders, multiple boxes are carefully stacked on wooden pallets and shrink-wrapped to maintain stability during shipping. All packages are clearly labeled with product details, handling instructions, and shipping information to facilitate smooth logistics and delivery.

We utilize trusted shipping carriers and offer various shipping options to meet delivery timeframes and budget requirements. Our packaging and shipping standards ensure that the Self-aligning Ball Bearings arrive safely and in optimal condition, ready for immediate use.

FAQ:

Q1: What is a self-aligning ball bearing?

A1: A self-aligning ball bearing is a type of bearing that has two rows of balls and a common spherical raceway in the outer ring. This design allows the bearing to accommodate misalignment between the shaft and housing without increasing friction or reducing performance.

Q2: What are the main applications of self-aligning ball bearings?

A2: Self-aligning ball bearings are commonly used in applications where shaft deflection or misalignment is expected, such as in agricultural machinery, electric motors, conveyors, and fans.

Q3: What materials are used in the construction of self-aligning ball bearings?

A3: These bearings are typically made from high-quality chrome steel for the balls and rings, with cages made from steel, brass, or synthetic materials depending on the application requirements.

Q4: How do self-aligning ball bearings handle misalignment?

A4: The spherical outer ring raceway allows the inner ring, balls, and cage to rotate freely even if the shaft is misaligned, thus reducing stress and preventing premature bearing failure.

Q5: What are the common sizes and load capacities available for self-aligning ball bearings?

A5: Self-aligning ball bearings are available in a wide range of sizes, typically from small diameters of a few millimeters up to large diameters of several hundred millimeters, with load capacities varying accordingly to suit light to heavy-duty applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!