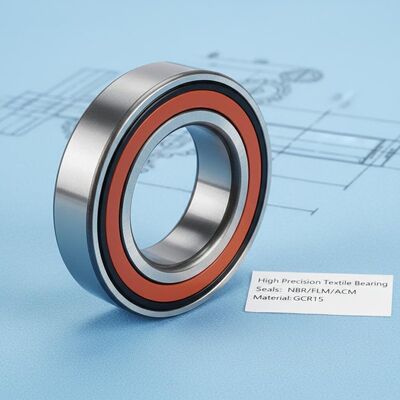

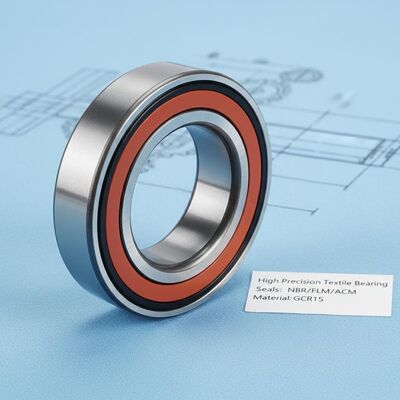

Product Description:

The Textile Bearing is a specialized type of bearing designed to meet the demanding requirements of various industrial applications where durability, reliability, and performance are critical. This product combines advanced materials and precision engineering to deliver exceptional functionality, making it an ideal choice for machinery and equipment that require smooth and efficient rotational movement. Known for its unique construction, the Textile Bearing is often referred to as a Woven Material Bearing, Textile Based Bearing, or Textile Sleeve Bearing, highlighting its distinctive integration of textile components within the bearing structure.

One of the key features of this Textile Bearing is the use of high-quality steel balls, available in Class G10 or G5. These steel balls are manufactured to stringent standards, ensuring excellent roundness, hardness, and surface finish. The availability of both G10 and G5 classes allows users to select the appropriate level of precision and durability based on their specific application needs. The steel balls are the core rolling elements that facilitate smooth motion and reduce friction within the bearing.

The Textile Bearing is designed as a single-row bearing, which means it contains one row of steel balls arranged between the inner and outer rings. This single-row configuration is advantageous in applications where moderate load capacity and compact design are essential. It provides a balanced combination of load handling and rotational speed, making it suitable for a wide range of machinery components such as motors, pumps, and conveyors.

The cage material used in the Textile Bearing can be either steel or plastic, offering flexibility depending on the operational environment. Steel cages provide robust support and excellent resistance to mechanical stress, making them suitable for heavy-duty applications. On the other hand, plastic cages are lighter and can reduce noise and vibration, which is beneficial in applications requiring quieter operation. This choice allows manufacturers and end-users to optimize the bearing performance by selecting the cage material that best suits their operational conditions.

Another important aspect of the Textile Bearing is its rubber seals, which are crucial for protecting the internal components from contaminants such as dust, moisture, and chemicals. The seals are made from high-quality rubber materials, including NBR (Nitrile Butadiene Rubber), FKM (Fluoroelastomer), and ACM (Polyacrylate Rubber). Each rubber type offers unique properties: NBR is known for its excellent resistance to oils and fuels, FKM provides superior chemical and temperature resistance, and ACM excels in high-temperature environments and resistance to ozone and weathering.

The rubber seals are constructed using a combination of NBR, ACM, or FKM with SPCC (cold-rolled carbon steel) backing, which enhances the structural integrity and durability of the seals. This composite seal design ensures a tight and reliable barrier against contaminants while maintaining flexibility and resilience over prolonged use. The use of these advanced sealing materials significantly extends the bearing’s service life and reduces maintenance requirements.

As a Woven Material Bearing, the Textile Bearing incorporates textile or fabric elements within its structure that contribute to its unique performance characteristics. These woven materials are engineered to provide enhanced lubrication retention, reduced friction, and improved wear resistance, which are essential for the longevity and reliability of the bearing. The Textile Sleeve Bearing variant further emphasizes the integration of textile components, often used as a lining or sleeve to facilitate smooth rotational motion and reduce metal-to-metal contact.

In summary, the Textile Bearing is a versatile and robust solution for numerous industrial applications. Its combination of high-quality steel balls (Class G10 or G5), single-row design, choice of steel or plastic cages, and advanced rubber seals (NBR, FKM, ACM combined with SPCC) ensures superior performance, durability, and protection against harsh operating conditions. Whether referred to as a Woven Material Bearing, Textile Based Bearing, or Textile Sleeve Bearing, this product stands out as a reliable component that enhances machinery efficiency and operational lifespan.

Features:

-

Product Name: Textile Bearing

-

Seal Type: Open, ZZ, 2RS

-

Cages: Steel or Plastic

-

Rubber Seals: NBR, FKM, or ACM

-

Rows Number: Single

-

Rubber Seals Materials: NBR/ACM/FKM + SPCC

-

Textile Based Bearing for enhanced durability and performance

-

Fiber Composite Bearing offering lightweight and high strength

-

Woven Material Bearing ensuring excellent wear resistance

Technical Parameters:

|

Seal Type

|

Open, ZZ, 2RS

|

|

Application

|

Transmission / Instruments

|

|

Rubber Seals Materials

|

NBR / ACM / FKM + SPCC

|

|

Speed Limit

|

Up To 3000 RPM

|

|

Noise Level

|

Low Noise Operation

|

|

Steel Balls

|

Tolerance G10

|

|

Cages

|

Steel Or Plastic

|

|

Steel Material

|

Chrome Steel, GCr15

|

|

Other Name

|

Ball Bearing Replacement

|

|

Rubber Seals

|

NBR Or FKM Or ACM

|

This Textile Based Bearing is a Fiber Composite Bearing designed for efficient and reliable performance in various transmission and instrument applications. As a Fiber Composite Bearing, it combines advanced materials and precise engineering to ensure durability and low noise operation.

Applications:

The Textile Bearing, also known as a Fiber Composite Bearing or Textile Based Bearing, is engineered to meet the demanding requirements of various industrial applications where durability, high precision, and wear resistance are paramount. This specialized bearing is designed using high-quality woven materials combined with advanced manufacturing techniques, ensuring exceptional performance in environments characterized by continuous motion and mechanical stress.

One of the primary application occasions for the Textile Bearing is in the textile manufacturing industry itself. Machinery used for weaving, spinning, and knitting requires bearings that can withstand constant friction and wear. The high wear resistance of this bearing, paired with steel balls manufactured to tolerance G10 standards, guarantees long service life and reliable operation even under high-speed conditions. Additionally, the high precision feature ensures smooth rotation and minimal vibration, which is critical for maintaining the quality and consistency of textile products.

Beyond traditional textile machinery, the Fiber Composite Bearing is also ideal for use in automated production lines involving woven materials. Its robust construction, including cages made from steel or plastic, provides flexibility in adapting to different operational environments. The rubber seals, crafted from materials such as NBR, ACM, or FKM combined with SPCC, offer excellent sealing performance, protecting the bearing internals from dust, moisture, and other contaminants. This makes the Textile Based Bearing highly suitable for use in harsh industrial settings where exposure to contaminants can significantly reduce bearing lifespan.

In addition, these bearings find extensive use in applications involving composite materials, especially where woven materials are integral to the product structure. The Textile Bearing’s unique design allows it to accommodate the specific mechanical stresses associated with fiber composite components, ensuring stability and precision in motion control systems. Industries such as aerospace, automotive, and advanced manufacturing benefit from the Textile Bearing’s ability to maintain performance under demanding conditions.

Overall, the Textile Bearing, with its combination of wear resistance, high precision, and versatile sealing and cage materials, is perfectly suited for a wide range of occasions and scenarios. Whether in textile machinery, fiber composite manufacturing, or other applications requiring woven material bearings, this product delivers reliable and efficient performance, making it an indispensable component in modern industrial operations.

Customization:

Our Textile Bearing products offer exceptional customization services tailored to meet your specific needs. Featuring a single row design, these fiber composite bearings ensure high precision and reliable performance in various applications.

Customers can choose between steel or plastic cages to optimize durability and weight according to their requirements. Additionally, our textile sleeve bearings come with multiple rubber seal options including NBR, FKM, or ACM, providing excellent resistance and sealing capabilities.

We also offer versatile seal types such as Open, ZZ, and 2RS to enhance the protection and longevity of the textile based bearing under different operating conditions. Trust our expertise to deliver customized textile bearing solutions that combine advanced materials and precision engineering.

Support and Services:

Our Textile Bearings are engineered to provide exceptional performance and durability in demanding textile industry applications. Designed to withstand high speeds, heavy loads, and exposure to lint and fibers, these bearings ensure smooth and reliable operation of textile machinery.

Technical support for Textile Bearings includes assistance with bearing selection, installation guidance, maintenance tips, and troubleshooting to maximize product life and efficiency. Our experts are available to help you optimize bearing performance tailored to your specific textile manufacturing processes.

We offer comprehensive services such as condition monitoring, bearing inspection, and replacement recommendations to prevent unexpected downtime. Additionally, customized solutions and upgrades are available to meet unique operational requirements.

By choosing our Textile Bearings and support services, you benefit from advanced engineering, quality materials, and a commitment to helping you achieve superior productivity in your textile operations.

Packing and Shipping:

Our Textile Bearings are carefully packaged to ensure maximum protection during transit. Each bearing is individually wrapped in protective materials to prevent contamination and damage. The bearings are then placed in sturdy, cushioned boxes designed to absorb shocks and vibrations.

For bulk orders, the products are securely stacked and palletized, ensuring stability throughout the shipping process. We use high-quality packing materials that comply with international shipping standards to maintain product integrity.

Shipping is handled by reliable carriers with tracking options available to provide real-time updates. We offer flexible shipping solutions to meet your requirements, including expedited and standard delivery services.

Upon receiving your Textile Bearing products, please inspect the packaging for any signs of damage and notify us immediately if any issues are detected. Our goal is to deliver your order safely and promptly, maintaining the highest standards of quality and customer satisfaction.

FAQ:

Q1: What materials are used in the construction of Textile Bearings?

A1: Textile Bearings are typically made from high-strength synthetic fibers combined with special lubricants to ensure durability, low friction, and resistance to wear and corrosion.

Q2: What are the main applications of Textile Bearings?

A2: Textile Bearings are widely used in industries such as automotive, aerospace, medical devices, and machinery where lightweight, low-friction, and maintenance-free bearing solutions are required.

Q3: How do Textile Bearings compare to traditional metal bearings?

A3: Textile Bearings offer advantages like reduced weight, self-lubrication, corrosion resistance, and quieter operation compared to traditional metal bearings, making them ideal for specific high-performance applications.

Q4: What temperature range can Textile Bearings operate within?

A4: Depending on the fiber and lubricant used, Textile Bearings can typically operate effectively in temperatures ranging from -40°C up to 120°C, ensuring reliable performance under various conditions.

Q5: Are Textile Bearings maintenance-free?

A5: Yes, Textile Bearings are designed to be maintenance-free due to their self-lubricating properties, which reduce the need for regular lubrication and minimize downtime.

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!