Product Description:

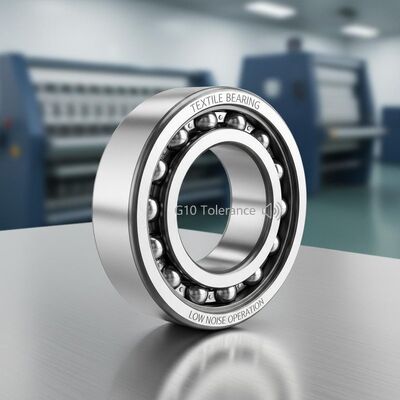

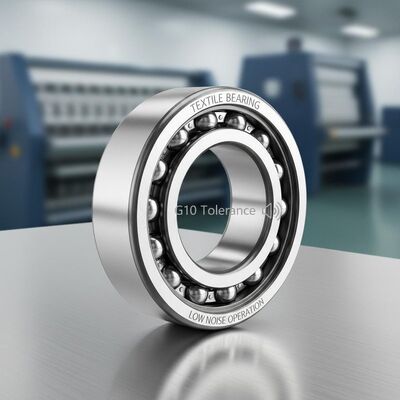

The Textile Bearing is a high-performance component designed specifically for applications requiring durability, precision, and low noise operation. This advanced bearing integrates superior materials and engineering to deliver exceptional performance in textile machinery and other industrial equipment. Known commonly as Textile Sleeve Bearing or Textile Based Bearing, this product stands out in the market for its reliability and efficiency.

One of the key features of this Textile Sleeve Bearing is the use of high-quality steel balls manufactured with a tolerance grade of G10. The G10 tolerance ensures that the steel balls maintain tight dimensional accuracy and consistency, which is critical for smooth and stable operation. These steel balls are crafted from premium chrome steel, specifically Gcr15, a material renowned for its excellent hardness, wear resistance, and fatigue strength. The use of Gcr15 chrome steel enhances the bearing’s durability and extends its service life, making it suitable for demanding textile industry environments where continuous operation is essential.

Seal configuration is another vital attribute of this Textile Based Bearing. The product offers multiple seal types, including Open, ZZ (double metal shield), and 2RS (double rubber seal), providing flexibility to meet various operational requirements. The open seal type allows for minimal friction and is suitable for applications where lubrication is frequent and contamination is low. The ZZ seal type offers protection against dust and other contaminants while minimizing friction, making it ideal for moderately harsh environments. Meanwhile, the 2RS seal type utilizes rubber seals on both sides, providing superior protection against moisture, dust, and other contaminants, thereby enhancing the bearing’s reliability in more challenging conditions.

The rubber seals used in the Textile Sleeve Bearing are made from carefully selected materials such as NBR (Nitrile Butadiene Rubber), ACM (Polyacrylate Rubber), and FKM (Fluoroelastomer), combined with SPCC (cold-rolled carbon steel) for structural integrity. These material combinations ensure that the seals maintain excellent elasticity, chemical resistance, and temperature tolerance, which are crucial for maintaining the bearing’s sealed environment and preventing ingress of contaminants. This robust sealing system plays a significant role in enabling the bearing to operate efficiently over extended periods while minimizing maintenance requirements.

One of the standout characteristics of this Textile Sleeve Bearing is its low noise operation. Noise reduction is a critical factor in many textile and industrial applications where quiet operation improves working conditions and reduces noise pollution. The optimized design, precision steel balls, and effective sealing contribute to a smooth, low-friction movement, ensuring that the bearing runs quietly and efficiently even under high-speed or heavy-load scenarios.

In summary, the Textile Bearing, also referred to as Textile Sleeve Bearing or Textile Based Bearing, is an expertly engineered product that combines premium materials, precision manufacturing, and flexible sealing options to meet the stringent demands of textile machinery and related industries. The use of G10 tolerance steel balls made from Gcr15 chrome steel ensures high performance and longevity, while the variety of seal types (Open, ZZ, and 2RS) and advanced rubber seal materials (NBR, ACM, FKM + SPCC) provide adaptability and protection for different environments. Its low noise operation further enhances its appeal as a reliable and efficient bearing solution. Whether for new machinery or replacement parts, this Textile Sleeve Bearing offers unmatched quality and performance to support the continuous operation and productivity of textile manufacturing processes.

Features:

-

Product Name: Textile Bearing

-

Woven Material Bearing construction for enhanced durability

-

Textile Sleeve Bearing design ensures smooth operation

-

Rubber Seals Materials: NBR, ACM, FKM combined with SPCC

-

Cages available in Steel or Plastic options

-

Operating Temperature Range: -40°C to 120°C

-

Seal Types: Open, ZZ, 2RS

-

Steel Material: Chrome Steel (GCr15) for high strength

-

Ideal for applications requiring Woven Material Bearing reliability

Technical Parameters:

|

Steel Balls

|

Tolerance G10

|

|

Steel Balls Class

|

G10 Or G5

|

|

Steel Material

|

Chrome Steel, Gcr15

|

|

Speed Limit

|

Up To 3000 RPM

|

|

Feature

|

High Precision

|

|

Seal Type

|

Open, Zz, 2RS

|

|

Operating Temperature Range

|

-40°C To 120°C

|

|

Rubber Seals

|

NBR Or FKM Or ACM

|

|

Cages

|

Steel Or Plastic

|

|

Wear Resistance

|

High

|

Applications:

The Textile Bearing, also known as a Textile Based Bearing, is a highly specialized component designed for applications requiring high precision and exceptional wear resistance. Its single row construction ensures optimal load distribution and smooth rotational movement, making it ideal for environments where accuracy and reliability are paramount. The bearing's cage can be made from either steel or plastic, allowing for flexibility depending on specific operational needs and environmental conditions.

One of the key materials used in this bearing is high-quality chrome steel, specifically GCr15, which is renowned for its durability and strength. This steel material contributes significantly to the bearing's high wear resistance, ensuring a longer service life even under continuous operation in demanding textile machinery. The use of GCr15 chrome steel enhances the bearing’s ability to maintain performance precision despite exposure to friction and mechanical stress.

Textile Sleeve Bearings, a variant within this product category, are particularly well-suited for applications involving woven materials. These bearings provide a smooth, low-friction interface that protects delicate textile fibers and woven structures from damage during processing. Their design helps reduce vibration and noise, which is critical in textile manufacturing environments where product quality and machine efficiency are closely monitored.

In practical scenarios, Textile Bearings are widely used in textile machinery such as spinning frames, weaving machines, and knitting equipment. Their high precision and wear-resistant properties enable consistent performance in high-speed operations and repetitive motion tasks. Additionally, the choice between steel or plastic cages allows these bearings to be customized for specific temperature ranges, chemical exposures, and lubrication conditions found in various textile production settings.

Moreover, the Woven Material Bearing variant excels in applications that involve direct contact with delicate woven fabrics. Its construction minimizes abrasion and mechanical wear on the fabric, ensuring that the integrity and quality of the textile product are preserved throughout the manufacturing process. This makes the bearing indispensable in high-end textile production where both machine longevity and product quality are critical.

Overall, Textile Based Bearings, including Textile Sleeve Bearings and Woven Material Bearings, are essential components in modern textile manufacturing. Their combination of high precision, single row design, steel or plastic cages, and superior wear resistance due to the GCr15 chrome steel material makes them the preferred choice for enhancing machine performance and ensuring the durability of textile products under rigorous operating conditions.

Customization:

Our Textile Based Bearing offers exceptional performance with high wear resistance and low noise operation, making it ideal for various industrial applications. The Textile Sleeve Bearing is designed with rubber seals made from premium materials such as NBR, ACM, and FKM combined with SPCC to ensure durability and reliability. Customers can choose from different seal types including Open, ZZ, and 2RS to suit their specific needs. This Woven Material Bearing features a single row design, providing efficient and smooth operation in demanding environments.

Support and Services:

Our Textile Bearing product is designed to provide exceptional performance and durability in demanding textile machinery applications. To ensure optimal operation and longevity, we offer comprehensive technical support and services tailored to your specific needs.

Technical support includes expert guidance on bearing selection, installation, and maintenance procedures to maximize efficiency and minimize downtime. Our team of specialists is available to assist with troubleshooting, performance optimization, and providing detailed product information.

We also offer customized maintenance programs and training sessions to help your staff understand the best practices for handling and caring for Textile Bearings. Additionally, our services include prompt replacement and repair options to keep your operations running smoothly.

By choosing our Textile Bearing product, you gain access to a dedicated support network committed to helping you achieve superior textile manufacturing outcomes through reliable and high-quality bearing solutions.

Packing and Shipping:

Our Textile Bearings are carefully packaged to ensure maximum protection during transit. Each bearing is individually wrapped in protective material to prevent contamination and damage. The wrapped bearings are then securely placed in sturdy boxes, with cushioning materials used as necessary to absorb shocks and vibrations.

For shipping, we use reliable carriers and provide tracking information for every order. Our packaging is designed to withstand various shipping conditions, ensuring that your Textile Bearings arrive in perfect condition and ready for immediate use.

FAQ:

Q1: What materials are used in the construction of Textile Bearings?

A1: Textile Bearings are typically made from high-quality synthetic fibers combined with advanced textile engineering to provide excellent durability, flexibility, and low friction performance.

Q2: What are the typical applications for Textile Bearings?

A2: Textile Bearings are commonly used in industries such as automotive, aerospace, medical devices, and industrial machinery where lightweight, corrosion resistance, and smooth operation are essential.

Q3: How do Textile Bearings compare to traditional metal bearings?

A3: Textile Bearings offer advantages including reduced weight, improved corrosion resistance, lower noise levels, and better performance in environments where lubrication is challenging.

Q4: Can Textile Bearings operate in high-temperature environments?

A4: Yes, Textile Bearings are designed to withstand a range of temperatures, though specific temperature limits depend on the fiber and resin systems used in their manufacture.

Q5: Are Textile Bearings maintenance-free?

A5: Many Textile Bearings are designed to be self-lubricating and require minimal maintenance, making them ideal for applications where regular servicing is difficult.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!