Product Description:

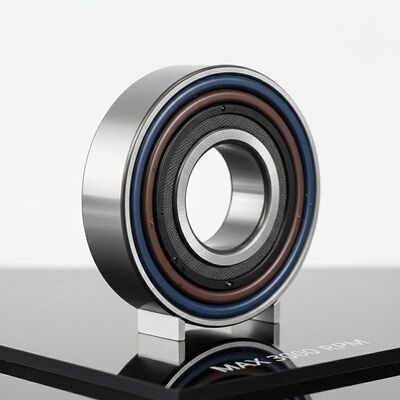

The Textile Bearing is an advanced solution designed to meet the demanding requirements of various industrial applications. Known for its exceptional durability and performance, this product is a prime example of innovation in the field of Fiber Composite Bearings. With a unique combination of materials and design features, the Textile Bearing offers outstanding reliability, especially in environments where traditional bearings may fail.

One of the key features of this Textile Sleeve Bearing is its use of high-quality rubber seals. Customers can select from NBR, FKM, or ACM rubber seals based on their specific application needs. These rubber seals ensure excellent resistance to wear, chemicals, and temperature variations, providing a tight barrier against contaminants and preserving the bearing’s internal components. Additionally, the rubber seal materials incorporate a combination of NBR, ACM, or FKM with SPCC, which enhances the sealing effectiveness and mechanical strength, making the bearing suitable for rigorous operating conditions.

This Textile Sleeve Bearing is designed as a single-row bearing, which simplifies installation and maintenance while delivering robust performance. The single row configuration allows for efficient load distribution and smooth operation, which is critical in applications where precision and reliability are paramount. Despite its simplicity, the bearing is engineered to handle speeds of up to 3000 RPM, making it suitable for a wide range of rotating equipment and machinery.

The bearing incorporates steel balls that are classified as either G10 or G5, representing high standards of precision and quality. The G10 and G5 classes refer to the tolerance and roundness of the steel balls, with G5 being the higher precision grade. This ensures that the Textile Sleeve Bearing operates with minimal friction and vibration, contributing to longer service life and enhanced performance. The use of high-grade steel balls also supports the bearing’s ability to sustain heavy loads and high-speed rotations.

As a Fiber Composite Bearing, this Textile Sleeve Bearing stands out for its exceptional combination of lightweight construction and high strength. The composite materials used in the bearing contribute to reduced weight without compromising durability, which is beneficial in applications where weight reduction is essential. Moreover, the composite nature of the bearing provides excellent resistance to corrosion and fatigue, making it ideal for use in harsh environments.

The Textile Sleeve Bearing is widely used in industries such as textile machinery, automotive components, electrical appliances, and precision instruments. Its ability to maintain performance under varying speeds and loads makes it a versatile choice for engineers and designers. The bearing’s effective sealing system, combined with the superior quality of steel balls and composite structure, ensures reliable operation and longevity.

In summary, the Textile Bearing offers a superior balance of material innovation, mechanical precision, and operational efficiency. With rubber seals available in NBR, FKM, or ACM, along with a combination of NBR/ACM/FKM+SPCC materials, it provides excellent protection and durability. The single-row design supports smooth rotation at speeds up to 3000 RPM, while the G10 or G5 steel balls guarantee high precision and reliability. This Fiber Composite Bearing, particularly in the form of a Textile Sleeve Bearing, is an excellent choice for applications requiring a durable, high-performance bearing solution that can withstand challenging operating conditions.

Features:

-

Product Name: Textile Bearing

-

Steel Material: Chrome Steel, Gcr15

-

Steel Balls Class: G10 or G5

-

Wear Resistance: High

-

Feature: High Precision

-

Rows Number: Single

-

Incorporates Textile Sleeve Bearing technology for enhanced durability

-

Utilizes Textile Based Bearing design for superior performance

-

Constructed with Woven Material Bearing elements for improved wear resistance

Technical Parameters:

|

Application

|

Transmission / Instruments

|

|

Wear Resistance

|

High

|

|

Steel Balls Tolerance

|

G10

|

|

Noise Level

|

Low Noise Operation

|

|

Rubber Seals

|

NBR Or FKM Or ACM

|

|

Operating Temperature Range

|

-40°C To 120°C

|

|

Speed Limit

|

Up To 3000 RPM

|

|

Rows Number

|

Single

|

|

Rubber Seals Materials

|

NBR/ACM/FKM+SPCC

|

|

Steel Balls Class

|

G10 Or G5

|

Applications:

The Textile Sleeve Bearing, also known as a Textile Based Bearing or Ball Bearing Replacement, is an essential component widely used in various textile machinery applications. Manufactured from high-quality chrome steel (GCr15), this bearing offers exceptional durability and resistance to wear, making it ideal for demanding industrial environments. Its robust steel material ensures a long service life even under continuous operation, which is critical in textile production lines where reliability is paramount.

One of the key advantages of the Textile Sleeve Bearing is its ability to operate efficiently within a broad temperature range of -40°C to 120°C. This feature allows it to perform consistently in diverse environmental conditions, from cold storage areas to high-temperature processing zones. Such versatility makes it suitable for use in spinning machines, weaving looms, and other textile equipment where temperature fluctuations are common.

The Textile Based Bearing is designed to handle speeds up to 3000 RPM, providing smooth rotational motion and minimizing friction losses. This speed limit aligns perfectly with the operational demands of many textile machines, ensuring optimal performance without compromising safety or bearing integrity. The steel balls used in these bearings are classified as G10 or G5, indicating high precision and quality standards that contribute to reduced vibration and noise during operation.

In textile manufacturing scenarios, the Textile Sleeve Bearing plays a crucial role in supporting rotating shafts and components, enhancing the overall efficiency and productivity of machinery. It is commonly applied in applications such as conveyor systems, knitting machines, and embroidery equipment where reliable, low-maintenance bearings are required. Additionally, its compatibility as a Ball Bearing Replacement means it can be easily integrated into existing setups, facilitating maintenance and reducing downtime.

Overall, the Textile Sleeve Bearing is a versatile and dependable solution for the textile industry, combining superior material properties with excellent operational capabilities. Whether in high-speed spinning or precision textile processing, this bearing ensures smooth and efficient machine performance, contributing to higher product quality and manufacturing consistency.

Customization:

Our Textile Bearing product offers exceptional customization services tailored to meet your specific needs. Featuring a single row design, this bearing utilizes steel balls with a tolerance class of G10, ensuring high precision and reliable performance. Also known as Ball Bearing Replacement, it is engineered to operate efficiently within a temperature range of -40°C to 120°C, making it suitable for a variety of demanding environments.

This Textile Sleeve Bearing is designed with advanced fiber composite materials, providing enhanced durability and reduced friction. As a leading Textile Based Bearing solution, it combines the strength of G10 class steel balls with innovative textile technology to deliver superior performance and extended service life.

Whether you require customized dimensions, specific operating conditions, or particular material properties, our product customization services guarantee a tailored solution that meets your exact requirements in the field of textile and fiber composite bearings.

Support and Services:

Our Textile Bearing products are designed to meet the rigorous demands of the textile industry, providing reliable performance and extended service life. For technical support, we offer comprehensive assistance including product selection guidance, installation instructions, and troubleshooting advice to ensure optimal operation.

We provide tailored maintenance services to help you maintain bearing efficiency and prevent unexpected downtime. Our expert team is available to assist with condition monitoring, lubrication recommendations, and replacement schedules.

Additionally, we offer training sessions and detailed documentation to empower your maintenance personnel with the knowledge to handle Textile Bearings effectively. For any technical inquiries or service requests, please refer to your local support channels.

Packing and Shipping:

Our Textile Bearing products are carefully packaged to ensure maximum protection during transit. Each bearing is securely wrapped in anti-corrosive paper and placed in a sturdy, cushioned box to prevent any damage.

The packaging is designed to maintain the integrity and cleanliness of the textile bearing, safeguarding it from moisture, dust, and mechanical impacts.

For shipping, we use reliable logistics partners that offer timely and safe delivery services. Each shipment is tracked and monitored to provide customers with real-time updates on their order status.

We also offer customized packaging solutions upon request to meet specific client requirements and ensure optimal handling during transportation.

FAQ:

Q1: What materials are used in the Textile Bearing?

A1: The Textile Bearing is made from high-quality synthetic fibers combined with durable polymers to ensure strength, flexibility, and long-lasting performance.

Q2: What are the main applications of the Textile Bearing?

A2: Textile Bearings are primarily used in industries requiring low-friction movement and wear resistance, such as automotive, aerospace, and industrial machinery.

Q3: How does the Textile Bearing perform under high temperature conditions?

A3: The Textile Bearing is designed to withstand temperatures up to 150°C (302°F) without compromising its structural integrity or performance.

Q4: Is the Textile Bearing suitable for wet or corrosive environments?

A4: Yes, the Textile Bearing is resistant to moisture and many chemicals, making it suitable for use in wet or mildly corrosive environments.

Q5: How do I maintain the Textile Bearing for optimal performance?

A5: Regular inspection and cleaning to remove debris are recommended. The Textile Bearing typically requires no additional lubrication due to its self-lubricating properties.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!