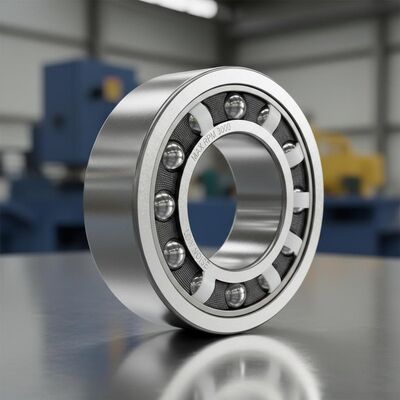

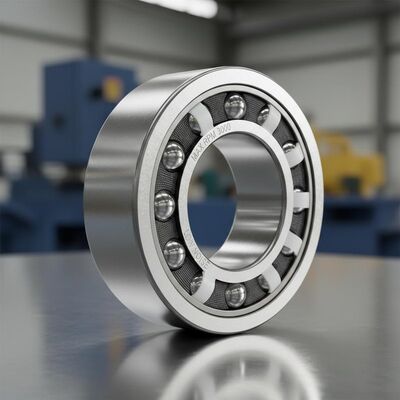

Product Description:

The Textile Bearing, also commonly known as the Ball Bearing Replacement, is an innovative and highly efficient component designed to enhance the performance and longevity of various mechanical systems. Engineered with precision and crafted to meet stringent quality standards, this bearing is an ideal choice for applications requiring durability, low noise, and reliable operation under moderate speeds. Its unique construction and material composition distinguish it as a superior option within the realm of fiber composite bearing technologies.

One of the standout features of this Textile Bearing is its use of steel balls with a tolerance grade of G10. This high level of precision ensures smooth rotation, reduced friction, and consistent performance throughout the bearing’s operational lifespan. The accuracy of the steel balls significantly contributes to minimizing wear and tear, thereby extending the service intervals and reducing maintenance costs. This attribute is especially important in applications where reliability and long-term stability are critical.

The Textile Bearing is designed with cages that can be made from either steel or plastic, offering versatility depending on the specific requirements of the application. Steel cages provide robust support and excellent resistance to deformation under heavy loads, making them suitable for demanding industrial environments. On the other hand, plastic cages reduce the overall weight of the bearing and contribute to quieter operation, which is advantageous in settings where noise reduction is a priority. This dual option allows users to select the optimal configuration for their needs, balancing durability and noise considerations effectively.

Speaking of noise, one of the key advantages of this Textile Bearing is its low noise operation. The combination of precision steel balls and carefully engineered cages ensures minimal vibration and sound generation during use. This feature is particularly beneficial in applications such as textile machinery, medical devices, or office equipment, where excessive noise can be disruptive or undesirable. The low noise characteristic enhances user comfort and contributes to a more pleasant working environment.

In terms of speed capabilities, the Textile Bearing can efficiently operate at speeds of up to 3000 RPM. This speed limit makes it suitable for a wide range of machinery and equipment that require moderate to high rotational velocity without compromising stability or safety. The bearing’s capacity to maintain performance at these speeds is a testament to its quality design and material selection, ensuring that it can handle dynamic loads and rotational stresses with ease.

As a Fiber Composite Bearing, the Textile Bearing incorporates advanced composite materials that offer improved resistance to corrosion, reduced weight, and better tolerance to harsh environmental conditions compared to traditional metal bearings. This textile-based bearing technology leverages the benefits of fiber composites to deliver a reliable and durable solution for modern industrial applications. The use of fiber composites also contributes to the bearing’s ability to operate efficiently under varying temperatures and exposure to contaminants, further enhancing its versatility.

In summary, the Textile Bearing, or Ball Bearing Replacement, is a high-performance fiber composite bearing designed to meet the demanding needs of contemporary mechanical systems. With steel balls manufactured to tolerance G10, options for steel or plastic cages, low noise operation, and a speed limit of up to 3000 RPM, this textile-based bearing offers unmatched reliability and efficiency. Its advanced material composition and engineering excellence make it an optimal choice for industries seeking durable, quiet, and high-speed bearing solutions. Whether used in textile machinery, automotive components, or precision equipment, this fiber composite bearing stands out as a dependable and innovative product that contributes significantly to operational success and equipment longevity.

Features:

-

Product Name: Textile Bearing

-

Material of Rubber Seals: NBR, ACM, FKM combined with SPCC

-

Available Seal Types: Open, Zz, 2RS

-

Rubber Seal Options: NBR, FKM, or ACM

-

Number of Rows: Single

-

High Precision design for superior performance

-

Constructed as a Textile Sleeve Bearing for enhanced durability

-

Incorporates Fiber Composite Bearing technology for strength and reliability

-

Ideal for applications requiring Textile Sleeve Bearing solutions

Technical Parameters:

|

Application

|

Transmission / Instruments

|

|

Wear Resistance

|

High

|

|

Rows Number

|

Single

|

|

Steel Material

|

Chrome Steel, Gcr15

|

|

Steel Balls

|

Tolerance G10

|

|

Steel Balls Class

|

G10 Or G5

|

|

Feature

|

High Precision

|

|

Other Name

|

Ball Bearing Replacement

|

|

Rubber Seals

|

NBR Or FKM Or ACM

|

|

Rubber Seals Materials

|

NBR/ACM/FKM+SPCC

|

Applications:

The Textile Sleeve Bearing, a highly specialized textile-based bearing, is designed to meet the rigorous demands of various industrial applications. One of the key features of this product is its incorporation of rubber seals made from high-quality materials such as NBR, FKM, or ACM. These seals ensure optimal protection against contaminants, dust, and moisture, thereby enhancing the overall durability and reliability of the bearing in harsh environments. With an operating temperature range from -40°C to 120°C, the Textile Sleeve Bearing is capable of maintaining its performance across a broad spectrum of working conditions, making it suitable for both low-temperature and high-temperature applications.

Steel balls used within this textile bearing are manufactured with strict tolerance standards, specifically tolerance G10, to guarantee smooth operation and minimal friction. The availability of steel balls in classes G10 or G5 further allows users to select the appropriate precision level based on their specific transmission or instrumentation needs. This precision in the steel balls ensures that the Textile Based Bearing can deliver consistent performance, reducing wear and extending service life.

The Textile Sleeve Bearing is especially advantageous in transmission systems where reliable movement and reduced noise are critical. Its textile-based construction provides excellent flexibility and vibration absorption, which helps in minimizing mechanical wear and tear. Additionally, this bearing is well-suited for use in various instruments, where precise and stable rotation is essential. Its resistance to temperature fluctuations and contaminants makes it ideal for sensitive instrumentation that operates in challenging environments.

In summary, the Textile Sleeve Bearing stands out as a versatile and robust solution for applications requiring dependable transmission and instrument bearings. Whether in industrial machinery, automation equipment, or precision instruments, the textile-based bearing’s advanced rubber seals, wide operating temperature range, and high-precision steel balls ensure optimal efficiency and longevity. These features collectively make the Textile Sleeve Bearing an excellent choice for engineers and manufacturers looking to enhance the performance and reliability of their mechanical systems.

Customization:

Our Textile Bearing product offers exceptional customization services to meet your specific requirements. Designed as a high-performance Woven Material Bearing, it supports speeds up to 3000 RPM, ensuring efficient operation in demanding textile applications.

We provide options for steel balls classified as G10 or G5 to suit different precision and durability needs. The bearing features customizable rubber seals available in NBR, FKM, or ACM materials, enhancing resistance to various environmental conditions.

Choose from cages made of steel or plastic, tailored to your application's load and speed demands. Additionally, our Fiber Composite Bearing options include multiple seal types such as Open, ZZ, and 2RS, providing versatility for protection against contaminants and lubrication retention.

With these comprehensive customization options, our Woven Material Bearing solutions are designed to optimize performance, longevity, and reliability in your textile machinery.

Support and Services:

Our Textile Bearings are engineered to provide exceptional performance and durability in demanding textile machinery applications. Designed with high-quality materials and precision manufacturing processes, these bearings ensure smooth operation, reduce friction, and extend the service life of your equipment.

For technical support, our expert team is available to assist with product selection, installation guidance, and troubleshooting to optimize your machinery's efficiency. We offer comprehensive services including bearing maintenance advice, condition monitoring, and replacement recommendations to minimize downtime and maximize productivity.

In addition, we provide customized solutions tailored to meet specific operational requirements and environmental conditions. Our commitment is to deliver reliable and efficient bearings that support your manufacturing processes and help achieve superior textile production quality.

Packing and Shipping:

Our Textile Bearings are carefully packaged to ensure maximum protection during transit. Each bearing is individually wrapped in protective material to prevent contamination and damage. The bearings are then placed in sturdy, cushioned boxes designed to withstand handling and shipping stresses.

For shipping, we use reliable carriers and provide tracking information to ensure timely delivery. All packages are labeled clearly with handling instructions to maintain the integrity of the Textile Bearings. We also offer customized packaging solutions upon request to meet specific customer requirements.

FAQ:

Q1: What materials are used in the Textile Bearing?

A1: The Textile Bearing is made from high-quality, durable fibers combined with advanced textile technology to ensure strength, flexibility, and resistance to wear.

Q2: What applications are suitable for Textile Bearings?

A2: Textile Bearings are ideal for applications requiring lightweight, corrosion-resistant, and low-friction components such as in automotive, aerospace, and industrial machinery.

Q3: How does the Textile Bearing perform under high temperatures?

A3: The Textile Bearing is designed to withstand elevated temperatures up to a certain limit, maintaining its structural integrity and performance in demanding environments.

Q4: Are Textile Bearings maintenance-free?

A4: Yes, Textile Bearings require minimal maintenance due to their self-lubricating properties and resistance to contaminants, reducing downtime and servicing costs.

Q5: Can Textile Bearings be customized for specific load requirements?

A5: Absolutely, Textile Bearings can be tailored in terms of size, shape, and fiber composition to meet specific load and operational demands.

يجب أن تكون رسالتك بين 20-3000 حرف!

يجب أن تكون رسالتك بين 20-3000 حرف! من فضلك تفقد بريدك الالكتروني!

من فضلك تفقد بريدك الالكتروني!  يجب أن تكون رسالتك بين 20-3000 حرف!

يجب أن تكون رسالتك بين 20-3000 حرف! من فضلك تفقد بريدك الالكتروني!

من فضلك تفقد بريدك الالكتروني!